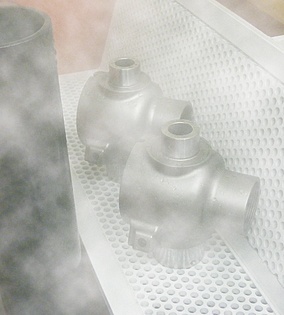

Quality, Responsive Critical Salt-Spray Testing On-Demand...

GSMP has provided critical and effective salt spray testing to industry manufacturers since 1987.

The salt spray test is a standardized test method used to check corrosion resistance of coated samples. Coatings provide corrosion resistance to metallic parts made of steel, zamak or brass. Since coatings can provide a high corrosion resistance through the intended life of the part in use, it is necessary to check corrosion resistance by other means. Salt spray testing is an accelerated corrosion test that produces a corrosive attack to the coated samples in order to predict its suitability in use as a protective finish. The appearance of corrosion products (oxides) is evaluated after a period of time. Test duration depends on the corrosion resistance of the coating; the more corrosion resistant the coating is, the longer the period of testing without showing signs of corrosion.

Salt spray testing is popular because it is inexpensive, quick, well standardized and reasonably repeatable. There is, however, only a weak correlation between the duration in salt spray testing and the expected life of a coating (especially on hot dip galvanized steel where drying cycles are important for durability), since corrosion is a very complicated process and can be influenced by many external factors. Nevertheless, salt spray testing is widely used in the industrial sector for the evaluation of corrosion resistance of finished surfaces or parts.