GSMP... Leaders in Providing Responsive, Quality

Magnetic Penetrant Inspection to the Metal Working Industry.

It’s not what we do, but how we perform that makes us valuable to our customers. With over 25 years in nondestructive testing specializing in Magnetic Particle and Liquid Penetrant inspection, our clients trust us withtheir most critical inspection projects.

GSMP is one of the West Coast’s few organizations with in-house ASNT Level-3 qualified personnel to ensure that your required testing projects are handled in the most professional and effective way. Single source testing services from GSMP when you need them.

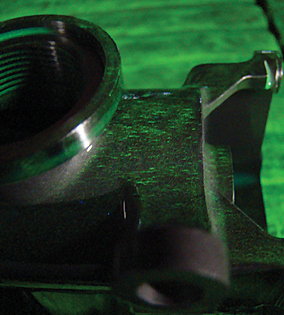

A brief overview on what Mag Testing is and how it can be applied. Magnetic Particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys and this process must be performed to worldwide standards such as EN473 and ISO9712 by qualified personnel. The process puts a magnetic field into the part. The part can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current which may be either alternating current (AC) or some form of direct current (DC) (rectified AC).