When Your Parts Require Abrasive Cleaning... Trust

GSMP To Do It Right!

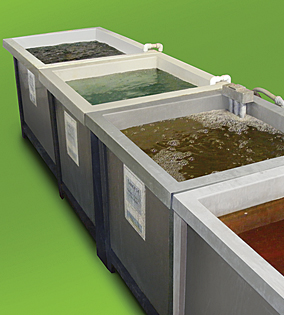

When your parts need to be clean trust the well trained personnel of GSMP to handle your most critical hardware. Our abrasive cleaning services provide you with the option of Glass Bead or Aluminum Oxide. We have multiple abrasive blast cabinets allowing us to ensure that your hardware is cleaned with material that does not get cross contaminated with several mediums. In addition to our cabinet options we also maintain stock in different grit sizes in both mediums used allowing us to offer you a wider range of finish options to meet your customer’s needs.

Abrasive cleaning is often overlooked as being a critical process, after all how difficult can it be. It actually is a very critical process in that it does in fact remove material and if performed improperly can dimensionally affect your hardware. It also impacts the finish of your part and the worst damage is if the medium is contaminated, it will be embedded into the material and could potentially pit and cause corrosion during any cleaning operations requiring the use of acid following the abrasive cleaning process. Here at GSMP we undergo the rigorous audit performed by PRI in the abrasive cleaning department in conjunction with our Chemical Processing approval from NADCAP.